Product Description

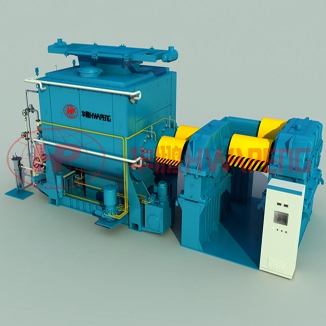

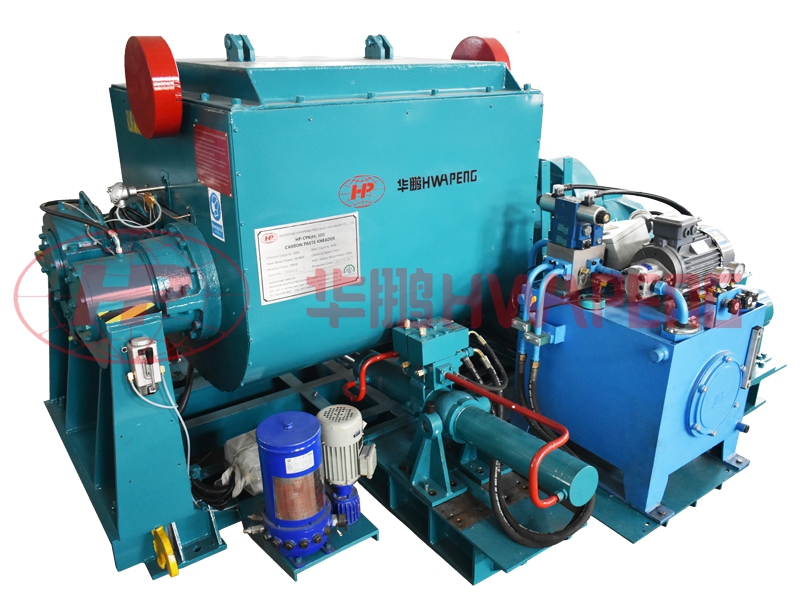

HP-CPK(H) Series Hydraulic Tilting (Electric Heating) Carbon Paste Kneader is a type of kneading machine. Its working process is to knead materials under electric heating. The kneaded paste is discharged by kneading tank tilting. Its advantage is that the discharge is thorough and there is no old material left in the machine, which can guarantee the quality of carbon. It adopts a number of patented technologies, and achieves excellent paste kneading quality, good sealing performance, no dust and asphalt smoke leakage.

Kneading is an important process in the production of carbon products. It mainly completes the kneading of dry materials and binder pitch, and endows paste with strong plasticity.

Under the function of kneading equipment, pitch infiltrates and merges the particle material and powder material, and wraps a uniform pitch film on the particle surface to form paste with good plasticity.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog