Product Description

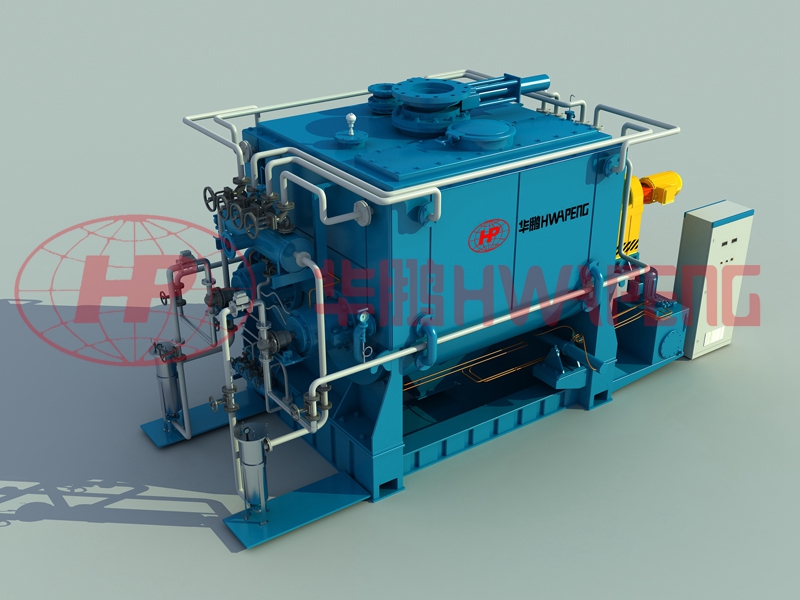

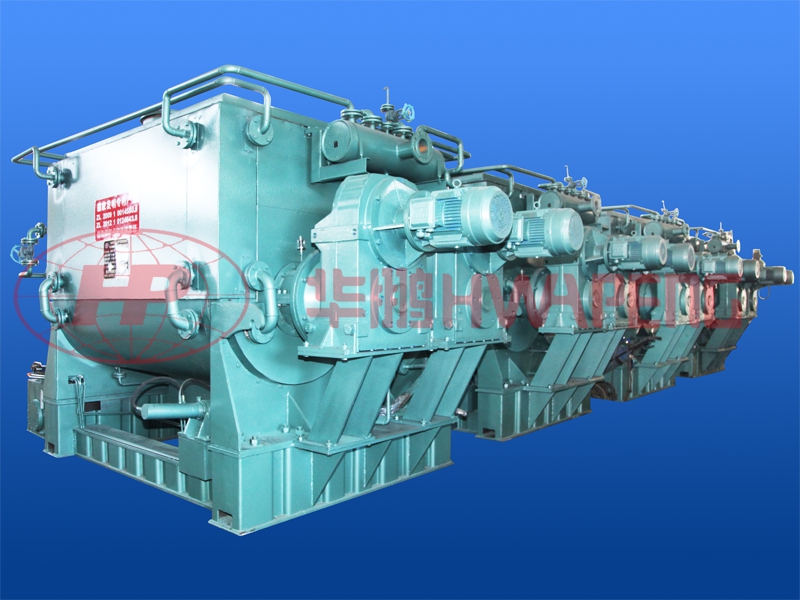

HP-DMH Series Dry Material Preheater adopts many heat transfer enhancement patented technologies, which can realize rapid and efficient mixing and preheating of dry materials.

Increasing the temperature of the dry material can keep the temperature of the added pitch constant, reduce the viscosity and the surface tension, and then reduce the surface wetting angle of the aggregate and the powder, which is conducive to the formation of the adsorption film on the surface of the aggregate and the powder.

On the one hand, the aggregate needs to be transported to the heating equipment for preheating after the completion of batching, so as to ensure a certain temperature when the aggregate and binder are mixed, so that the pitch can penetrate into the pores of the aggregate well, which is more conducive to the filling and surface coverage of the pores of the aggregate particles by pitch, and to improve the paste density and plasticity.

On the other hand, pitch is a kind of hydrophobic and lipophilic material. Water film can significantly reduce the infiltration of pitch on aggregate particles, so preheating can remove the water in the aggregate and improve the bulk density of carbon products.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog