Product Description

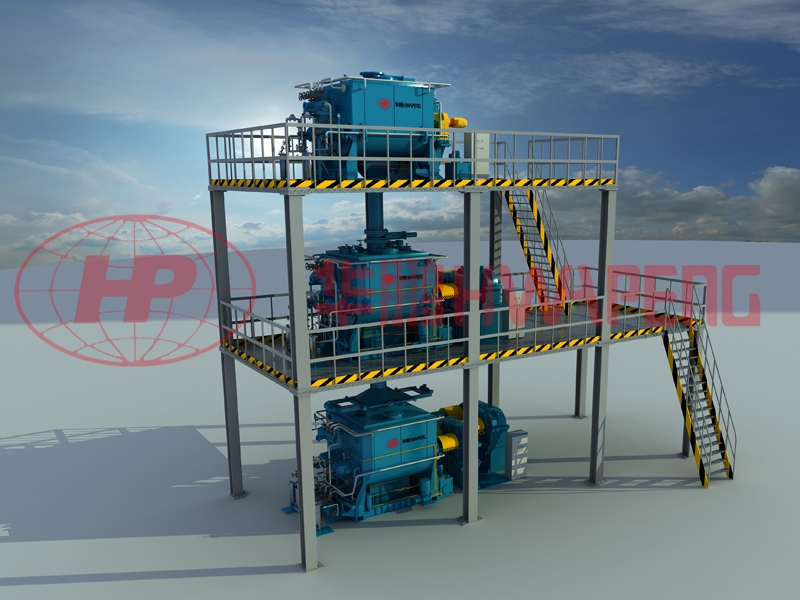

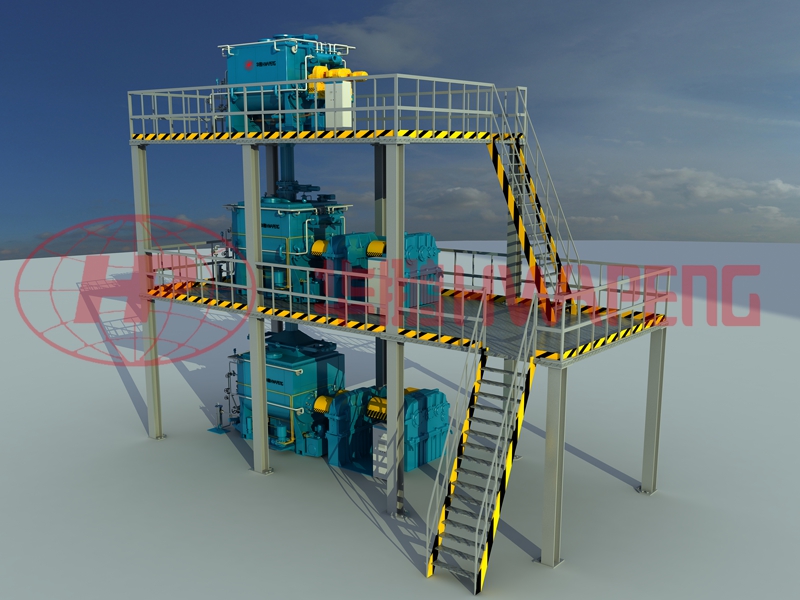

HP-H(H)KC Series High Efficient Preheating Kneading Cooling System is mainly used in the preparation of paste in carbon industry, for the production of prebaked anode, aluminum cathode, graphite electrode, special graphite and other products. After the aggregate is heated to the specified process temperature in the preheating machine, it enters the kneading machine to complete the kneading of the dry material and the binder pitch, forming paste with good plasticity, and the paste enters the cooling machine to be cooled to the specified forming temperature.

HP-H(H)KC High Efficient Preheating Kneading Cooling System is equipped with new efficient high-temperature tank, high-efficient high-temperature mixing blade, safety monitoring system of rotary joint, new sealing device of mixing blade shaft end, safety protection device of mixing blade, real-time monitoring system of mixing blade, pitch uniform feeding device, transmission system with strong bearing capacity and reliable operation, convenient replacement of lining plate, accurate temperature measuring device, etc, to ensure the operation of equipment is efficient, stable and reliable.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog