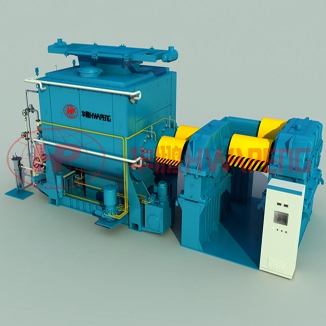

Product Description

HP-DHK series double-layer preheating kneading machinedoubles production efficiency, saves 50% of electricity, and saves equipment investment by 50%. In 2009, it was approved by the China Carbon Industry Association, the well-known Shenyang Aluminum Magnesium Design Institute Co., Ltd., Guiyang Aluminum Magnesium Design and Research Institute Co., Ltd. and several domestic well-known carbon experts to participate in the assessment of provincial and ministerial scientific and technological achievements.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog